TEL:400-0033-603

------- 实验室预约 --------

微信公众号

浏览量:

产品名称

1200℃ 64L箱式炉 MF-1200C-L

所属分类

箱式炉系列

零售价

0.00

数量

-

+

库存

0

联系我们

在线咨询

产品描述

产品参数

①保温材料采用真空吸附成型的氧化铝纤维无机材料,环保节能,不含污物,洁净,美观。

②采用模糊PID控制,智能PID精准控制,温场均匀,烧结成品一致性。

③炉体采用双层风冷机构,炉子烧到最高温度时,壳体表面温度低于60度。

④用多种保温材料组合制成,使炉子体积小,能量消耗少。

|

设备相关视频 |

|

|

炉子结构 |

采用高纯氧化铝作为炉膛材料,最大程度减小能量损失,比一般加热炉减少30%能耗 |

|

炉体采用双层结构,中间设置风道,保证炉体表面温度和电气控制部分温度不超过60℃ |

|

|

采用弹簧门扣,很好的解决了设备内膛因高温产生的收缩缝隙 |

|

|

额定功率 |

6KW |

|

额定电压 |

AC 208-240V Single Phase,50/60Hz |

|

最高温度 |

1200℃ |

|

工作温度 |

≦1100℃ |

|

推荐升温速率 |

5-20℃/min |

|

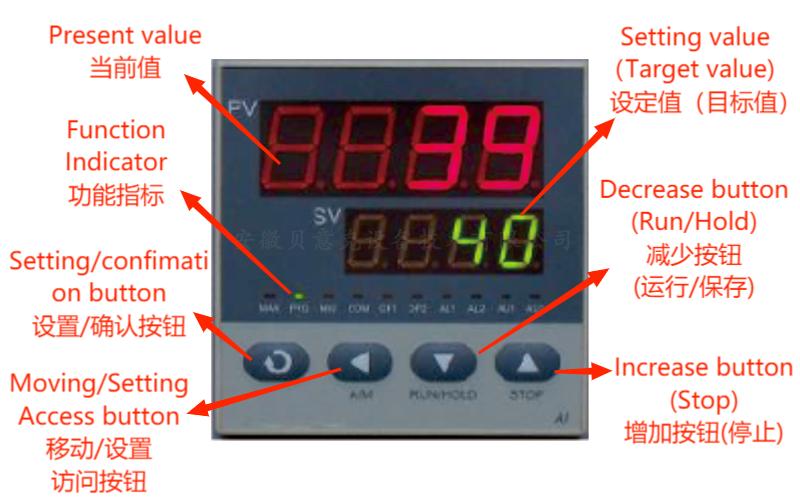

控温方式 |

全自动PID控制和自整定调节,智能化30段可编程控制,超温和断偶报警功能 |

|

热电偶 |

K型热电偶 |

|

控温精度 |

±1℃ |

|

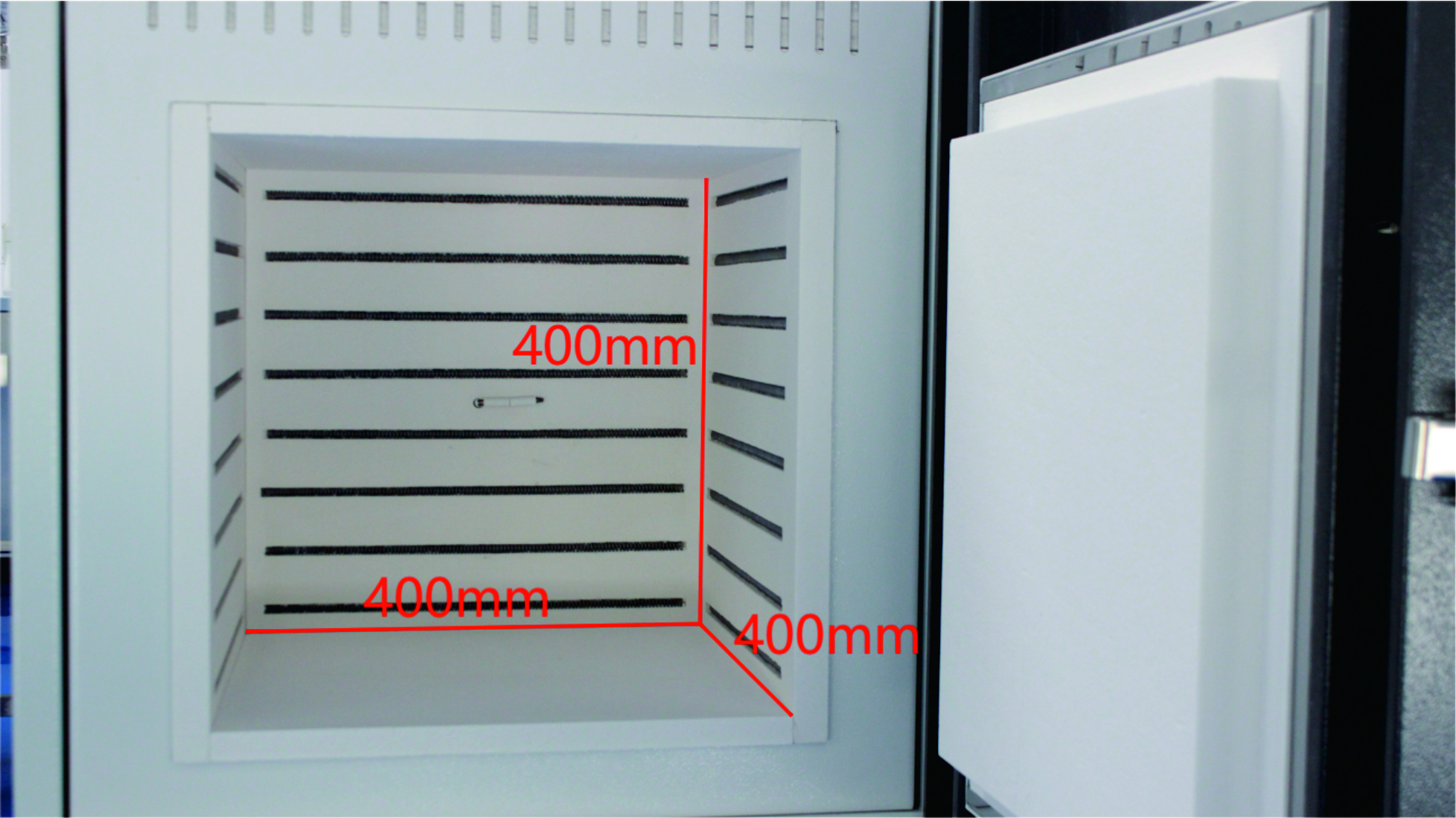

尺寸 |

腔体尺寸 400*400*400mm(64L) |

|

外形尺寸 670*630*1010mm |

|

|

包装尺寸 800*720*1250mm |

|

|

加热元件 |

电阻丝 |

|

净重 |

143Kg |

|

毛重 |

172Kg |

|

质保 |

质保周期一年(易损易耗件除外) |

|

警示 |

此设备腔体不密封,不能通入有毒有害,易燃易爆气体。可以加装进气接头,通惰性气体或者氧气 |

|

在使用过程中炉膛表面可能出现细小裂纹。这是正常情况,裂纹可以用氧化铝涂层修复 |

|

|

建议将样品放进坩埚里。不要把样品直接放在腔底 |

|

|

标准配置 |

垫砖、高温手套、坩埚钳 |

|

认证 |

CE认证 可付费进行TUV(UL61010)或CSA认证 |

上一篇

1100℃ 64L箱式炉 MF-1100C-L

无

下一篇