TEL:400-0033-603

------- 实验室预约 --------

微信公众号

浏览量:

产品名称

1200℃开启式管式炉 BTF-1200C

所属分类

1200℃管式炉

零售价

0.00

数量

-

+

库存

0

联系我们

在线咨询

产品描述

产品参数

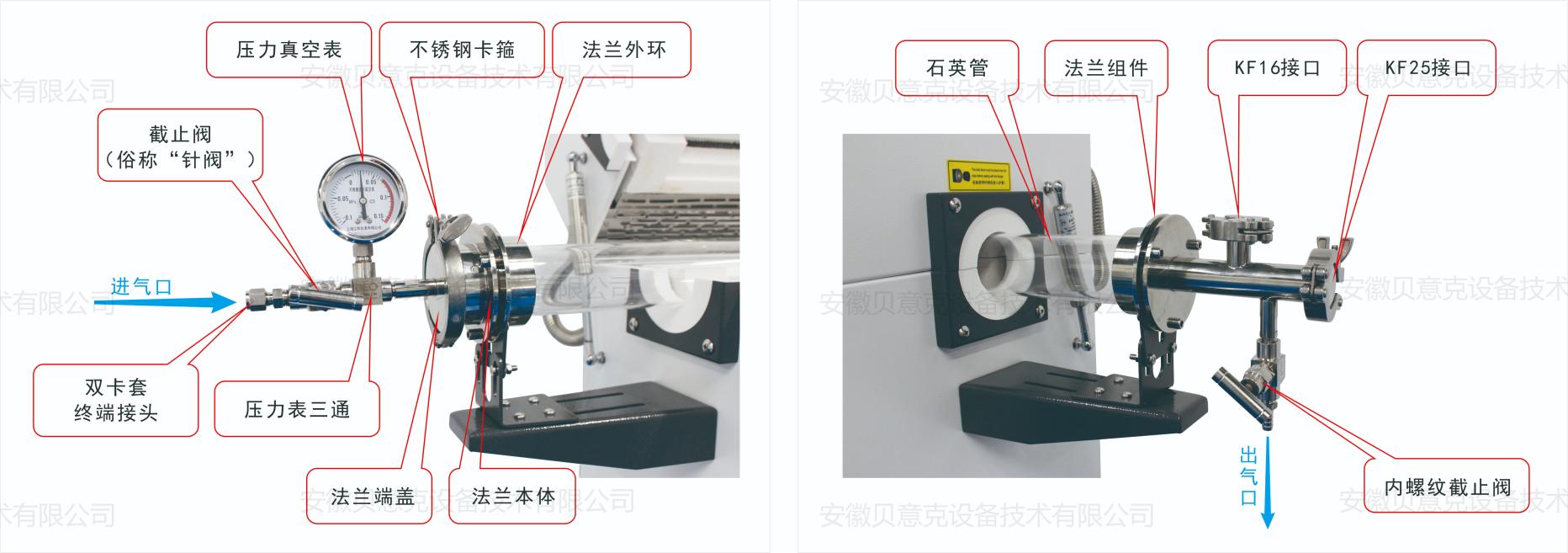

1、可以抽真空,也可以通气体保护;

2、开启式使得拆装炉管方便,操作简捷;

3、可直接将密封腔体移出炉体,加快降温过程;

4、可直观的看到样品烧结状态;

5、卡箍法兰减去了取放料时的繁琐操作;

6、炉膛材料采用高纯氧化铝纤维,能最大程度减少能量损失;

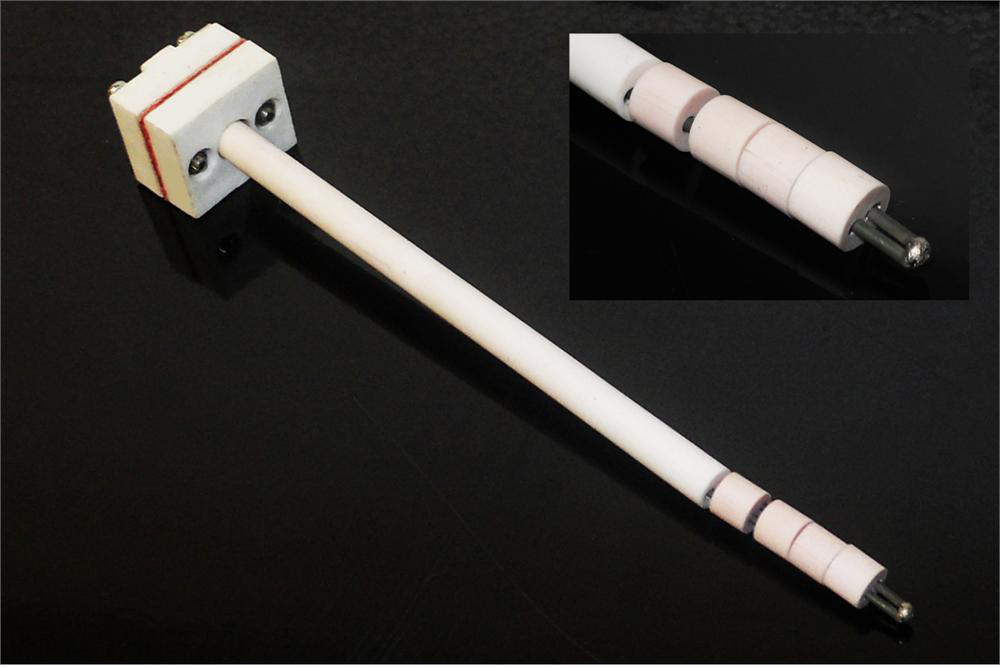

7、上下各6组进口电阻丝的炉膛,温场均匀;

8、气动弹簧支撑结构让操作者可各角度安全开启。

上一篇

1200℃迷你型开启式真空管式炉 BTF-1200C-S

1200℃磁力拉杆管式炉 BTF-1200C-CL

下一篇